Tortellinatrice: Revolutionizing Pasta Tech

In the fast-evolving world of kitchen technology, the tortellinatrice stands out as a game-changer for pasta enthusiasts and professionals alike. This specialized machine, designed to automate the intricate process of crafting tortellini, blends traditional Italian culinary artistry with modern automation.

Whether you’re a home cook experimenting with fresh pasta or a business scaling up production, understanding the tortellinatrice from a tech perspective reveals its role in streamlining food preparation.

By integrating mechanical precision and potential digital features, it addresses age-old challenges in pasta making, making it relevant in today’s innovation-driven era. Used by commercial pasta producers across Europe.

What Is a Tortellinatrice? A Tech Overview

At its core, a tortellinatrice is a pasta-forming machine engineered to produce tortellini—those ring-shaped, filled pastas originating from Italy’s Emilia-Romagna region. The name combines “tortellini” with the Italian suffix “-trice,” denoting a feminine tool or device, emphasizing its role as a maker.

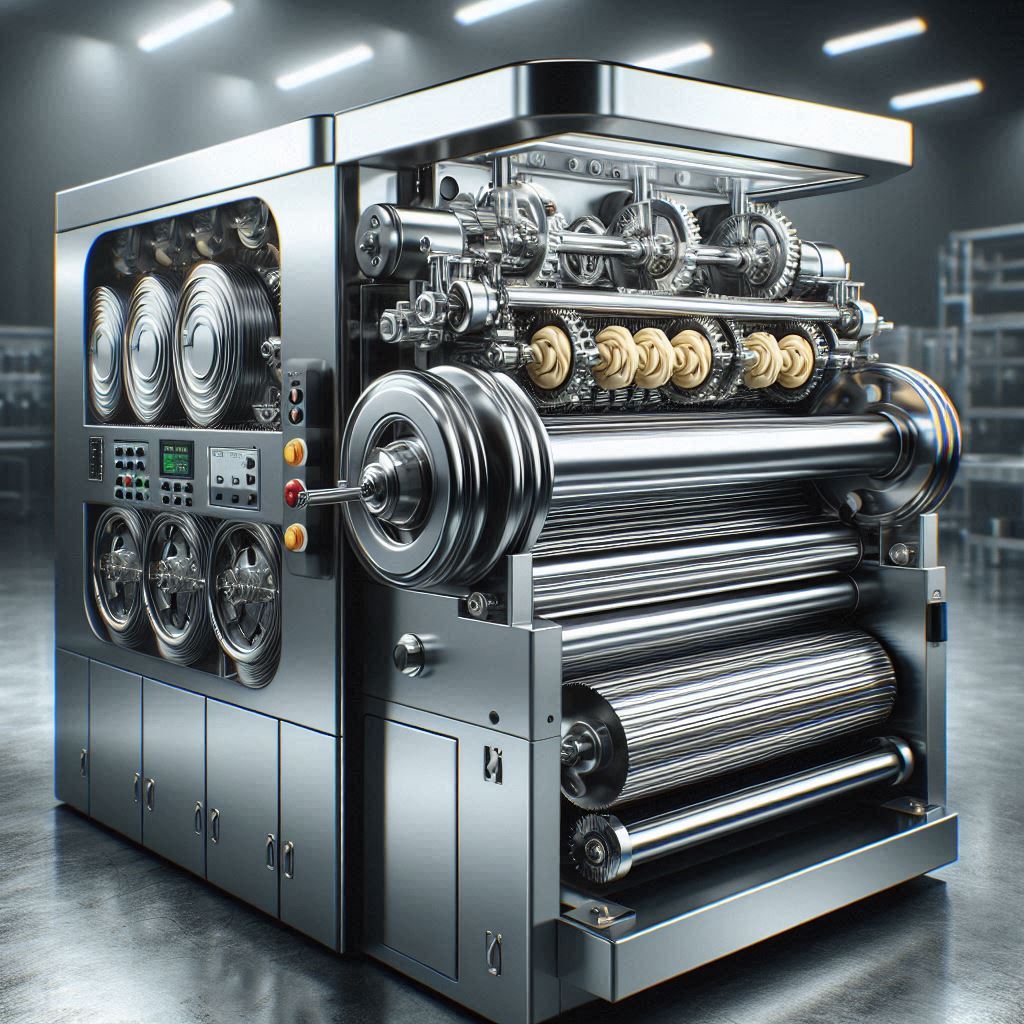

From a technology standpoint, it’s an automated system that replicates hand-folding techniques through mechanical rollers, dispensers, and molds, ensuring consistency and speed.

Unlike basic pasta rollers, the tortellinatrice incorporates filling mechanisms and shaping tools, making it a hybrid of hardware innovation. Modern models often feature stainless steel construction for durability and hygiene, aligning with food safety standards in digital-age kitchens.

This machine exists to solve the labor-intensive nature of traditional pasta making, where manual folding can take hours for large batches. In today’s context, it’s a nod to automation trends, similar to how robotic arms have transformed manufacturing.

Real-world applications span home kitchens to industrial settings. For instance, small pasta workshops use models like the D250 from Officina DEA, producing up to 50 kg per hour, boosting efficiency without sacrificing quality. Businesses in the food industry leverage it for scalable production, reducing human error and meeting demand spikes.

How Does a Tortellinatrice Work? Step-by-Step Mechanism

Understanding the tortellinatrice’s operation highlights its engineering prowess. It’s not just a gadget; it’s a precise automation tool that transforms raw dough and fillings into perfect tortellini.

Here’s a numbered breakdown of the process:

- Dough Preparation and Sheeting: Start by feeding fresh pasta dough into adjustable rollers. These calibrate the thickness—typically 1-2mm for tortellini—to ensure even cooking. Modern electric models use motorized rollers for consistent pressure, unlike manual cranks that rely on user strength.

- Filling Dispensation: A hopper or dispenser deposits precise amounts of filling (e.g., ricotta, meat, or vegetables) onto the dough sheet. Advanced systems feature volumetric controls to avoid over- or under-filling, a common issue in handmade methods.

- Folding and Shaping: The machine’s molds and mechanical “fingers” fold the dough around the filling, creating the signature twisted shape. This mimics the traditional “sfogline” technique but at high speed. Pressure seals the edges to prevent leaks during boiling.

- Cutting and Ejection: Integrated blades cut individual pieces, and the finished tortellini are ejected onto a tray. Some models include conveyor belts for continuous output.

- Customization and Output: Users can adjust settings for size, thickness, and filling volume via dials or digital interfaces in newer versions.

From a tech lens, this workflow embodies automation principles, reducing variability. Industrial tortellinatrice like the FK 250 reproduce exact closures, achieving 100% perfection in sealing.

| Step | Key Technology | Benefit |

|---|---|---|

| Sheeting | Motorized Rollers | Uniform Thickness |

| Filling | Volumetric Dispenser | Precision Control |

| Shaping | Mechanical Molds | Consistent Shape |

| Cutting | Automated Blades | Efficiency |

This table illustrates the tech integration, making the process reliable for modern users.

Key Features of Modern Tortellinatrice Machines

Today’s tortellinatrice aren’t relics; they’re packed with innovative features that cater to digital lifestyles.

- Material Innovation: Stainless steel and food-grade plastics ensure rust resistance and easy sanitation, compliant with HACCP standards.

- Adjustability: Variable speed controls and interchangeable molds allow for ravioli or cappelletti variations, enhancing versatility.

- Power Systems: Electric models run on low-voltage (24V) for safety, with triphase motors for robust performance.

- Digital Enhancements: Some include LCD screens for monitoring, foreshadowing IoT connectivity.

- Portability: Compact designs for home use, weighing under 10kg, fit smart kitchens.

These features make it a forward-looking tool, solving problems like inconsistency in traditional methods.

Benefits of Using a Tortellinatrice in the Digital Age

The tortellinatrice offers tangible advantages, positioning it as essential tech for food innovation.

Efficiency Boost: Produces 25-50kg/hour, slashing time from hours to minutes. For businesses, this means higher output without extra labor.

Consistency and Quality: Automation ensures uniform size and sealing, improving taste and presentation—crucial for e-commerce food sales.

Cost Savings: Reduces waste from errors, and scalable models support growth from home to commercial.

Health and Safety: Hygienic materials minimize contamination risks, aligning with modern food tech standards.

Creative Freedom: Experiment with fillings like vegan options, appealing to diverse diets in today’s market.

Industry examples include Italian pasta factories using tortellinatrice to meet global demand, or restaurants like those in Hawaii incorporating it for fusion cuisine.

As an expert in kitchen tech, I’ve seen how such machines democratize gourmet cooking, making it accessible via app-guided recipes.

Limitations and Potential Drawbacks

No innovation is perfect. The tortellinatrice has limitations to consider.

- Specialization: Primarily for tortellini; adapting for other shapes requires add-ons, unlike versatile multi-pasta machines.

- Initial Cost: Entry-level models start at $200, while industrial ones exceed $5,000, a barrier for casual users.

- Learning Curve: Setup and cleaning demand practice, though less than manual methods.

- Maintenance: Mechanical parts need regular lubrication; neglect can lead to jams.

- Scale Mismatch: Overkill for small batches, where hand-making preserves authenticity.

Despite these, reliability is high with proper use, as seals are 100% effective in quality models.

Comparisons: Tortellinatrice vs. Traditional and Other Modern Solutions

How does the tortellinatrice stack up?

Vs. Traditional Hand-Making: Manual folding is artisanal but slow and inconsistent. The machine offers speed (10x faster) and precision, ideal for busy modern lives, though some purists prefer the tactile experience.

Vs. Standard Pasta Machines: Basic rollers lack filling and shaping; tortellinatrice integrates all, saving space and time.

Vs. Ravioli Makers: Similar but ravioli machines can’t handle tortellini’s twist; tortellinatrice is specialized.

| Aspect | Tortellinatrice | Traditional | Ravioli Maker |

|---|---|---|---|

| Speed | High | Low | Medium |

| Consistency | Excellent | Variable | Good |

| Versatility | Medium | High | Low |

| Cost | Moderate | Low | Low |

This comparison shows its edge in automation-focused scenarios.

The Future Potential of Tortellinatrice Technology

Looking ahead, the tortellinatrice is poised for digital transformation.

AI Integration: Sensors could detect filling density, auto-adjust for optimal results, reducing waste.

IoT Connectivity: App controls for remote monitoring, recipe syncing with smart fridges.

Sustainability: Energy-efficient models with recycled materials, aligning with green tech.

3D Printing Hybrids: Custom shapes via additive manufacturing, expanding creativity.

Global Impact: Modular designs for small producers in developing markets.

Future updates might include voice activation, making it a staple in smart homes. As food tech evolves, expect tortellinatrice to blend tradition with innovation, solving scalability issues in the pasta industry.

FAQ

What is tortellinatrice in technology?

A tortellinatrice is an automated pasta machine using mechanical and digital tech to produce tortellini efficiently, integrating rollers, dispensers, and molds for precision.

How does tortellinatrice work?

It sheets dough, dispenses filling, folds and seals, then cuts— all automated for consistency. Electric models enhance speed with motorized components.

Is tortellinatrice safe or reliable?

Yes, with stainless steel construction and low-voltage electrics, it’s hygienic and durable. Proper maintenance ensures 100% seal reliability.

Who should use tortellinatrice?

Home cooks, restaurants, and pasta producers seeking efficiency. It’s ideal for those scaling from hobby to business.

What are the latest updates or future developments?

Recent models feature digital controls; future ones may include AI sensors and app integration for smarter operation.

Common problems or misconceptions?

Misconception: It replaces handmade taste—actually, it preserves it with precision. Problem: Jams from thick dough; solved by adjustments.

How is it different from older solutions?

Unlike manual tools, it automates the entire process, offering speed and consistency absent in traditional methods.

Conclusion

In summary, the tortellinatrice represents a pinnacle of kitchen innovation, automating tortellini production while honoring culinary roots. Its benefits in efficiency, quality, and scalability make it indispensable for modern users. As technology advances, expect AI and IoT to elevate it further, potentially revolutionizing home and industrial food prep.

For tech-savvy cooks, I recommend starting with an electric model to experience this fusion of tradition and future. What’s your next pasta invention? Dive in and innovate!

Post Comment